The Cache Titanium was our first non-suspension bike and our first product in titanium.

In the below, Noel talks about the challenges of building a product in titanium and why it is arguably the most difficult material to work with of the four common frame building materials (carbon, aluminum, steel and titanium).

This of course begs the question: if titanium is such a pain in the ass to work with, why use it when carbon, steel and aluminum can all be used to create great products?

The simple answer is that none of those materials can reproduce a well- made titanium frame’s unsurpassed ride quality and feel. Add in the longevity of titanium (completely corrosion resistant and essentially unlimited fatigue cycle), and the value only increases.

Knolly being both an engineering and experienced based company, we knew from the start that the Cache had to be launched in titanium. We wanted to design it differently than other titanium bikes on the market and create something truly new and innovative.

So, what does it take to create something new in titanium? Well, it depends what you mean by “new”. If new means custom geometry, then there are many high-end shops and craft builders who can work with customers to create a common vision of their dream bike. For us, new meant something different: a gravel product based on ultra-modern off road influenced multi-surface geometry and full control over the design and execution of every single part in the frame.

While we were new to the titanium market space, Noel was confident that there was not another bike company working in titanium at this foundational level, apart from perhaps Cane Creek’s awesome eeWings titanium crankset.

If you’re looking at the high-end world of titanium you’ll find that the vast majority of tubesets and machined parts come from a very small group of suppliers: 3, maybe 4 of them. Almost every high-end titanium frame on the market is made from a combination of parts provided from these suppliers.

Now, that leads to hundreds of possible configurations and of course unlimited geometry options from custom builders, but everyone is still using essentially the same pool of tubesets and CNC machined or cast parts (dropouts, brake mounts, BB shells, drive side yokes, etc…). There are a lot of options but not an infinite amount and surprisingly, none of them provided what we wanted for our bike.

So, we engaged one of these select titanium suppliers and discussed with them what we wanted to do. They gently laughed, and told us that what we wanted to do was almost impossible (claiming that you can’t manipulate titanium tubing like you can aluminum tubing). I replied: “Yes, it can be done and you are probably the only factory that can do it. But it’s extremely difficult, requires a bunch of custom tooling and the patience to develop a tube so that it can be made in a production environment.” After more discussion, they agreed with us. Development started and we invested in custom, multistage tube forming tooling (it even sounds cool)!

One of the key elements in particular was the design of the Cache’s seat tube. Making tapered tubing in titanium is done quite frequently. Making butted tubing in titanium is done quite frequently. Making formed and bent tubing in titanium is done quite frequently. But, doing all three operations in the same section of tubing is highly non-trivial and will almost always result in unusable cracked and crinkled tubes due to titanium’s propensity to work harden. Fifteen months after our initial discussion with our vendor and four separate production tools later, we had our first successful seat tube samples.

The seat tube that we’ve designed for the Cache is the most difficult tube to manufacture and we’re not aware of anything like it on any other titanium product in the market, anywhere. We originally identified four key features that we needed in this tube that required extreme manipulation: tire and fender clearance for relatively short chainstays meant that it needed to be bent. This bend and offset design would provide additional vertical compliance through the seat post to the rider. High torsional stiffness (i.e. high pedaling efficiency and aggressive cornering ability) meant that the tube needed to keep its width and fully internal cable routing – without exiting the down tube and re-entering the seat tube - meant that it needed to be welded fairly far up the down tube. These last two features required that the tube have a significant taper to it, right where it was bent around the rear wheel. And we wanted this in an elegant shape. To put it mildly, for a tube that looks so natural and subtle in person, it required a huge amount of work.

High torsional stiffness (i.e. high pedaling efficiency and aggressive cornering ability) meant that the tube needed to keep its width and fully internal cable routing – without exiting the down tube and re-entering the seat tube - meant that it needed to be welded fairly far up the down tube. These last two features required that the tube have a significant taper to it, right where it was bent around the rear wheel. And we wanted this in an elegant shape. To put it mildly, for a tube that looks so natural and subtle in person, it required a huge amount of work.

But it’s not the only custom tube in the Cache frame. In fact of the seven frame tubes (top tubes, down tubes, seat tube, chain stay and seat stay), all are custom and most of them required completely new or modified production tooling. By completely controlling the shapes and thicknesses of our tubing, we were able to not only define the ride characteristics of the Cache, but also incorporate features that are not found on any other titanium frames in the market. Particular attention was paid to cable routing allowing for super clean and efficient internal and external cable routing options

In fact of the seven frame tubes (top tubes, down tubes, seat tube, chain stay and seat stay), all are custom and most of them required completely new or modified production tooling. By completely controlling the shapes and thicknesses of our tubing, we were able to not only define the ride characteristics of the Cache, but also incorporate features that are not found on any other titanium frames in the market. Particular attention was paid to cable routing allowing for super clean and efficient internal and external cable routing options

This is especially obvious in the chainstays where the cross-section changes from a classic oval shape near the BB and tire, to trapezoidal at the dropouts. This was done for two reasons: it increases the weldable area for the flat mount disc brake mounts next to the non-drive side dropout and it provides an angled surface for the rear derailleur cable to exit the chain stay slightly away from the frame. This allows the rear derailleur cable to avoid the chain and naturally goes around the drive side dropout to interface with the rear derailleur.

While we know that the majority of Cache customers will no doubt install a rigid fork on their bike (and we’ll discuss our in-house Cache carbon fork in more detail in another blog post), being predominantly a mountain bike company, we wanted to ensure that customers who want to build essentially a much more modern 1993 titanium hardtail MTB with drop bars could throw today’s equivalent of a Mag 21 fork on their Cache!

This meant that we needed to bend a very large diameter titanium downtube near the headtube. We needed the down tube to be strong and to create a stiff frame, but we also wanted to ensure that we had clearance for short travel gravel specific suspension forks. We also bi-ovaled the down tube to both increase its width at the BB (again, better pedaling efficiency and cornering stiffness) and allow room for a custom CNC machined gusset plate for internal cable management.

Our heavily manipulated (tapered and bent) seat stays provide enhanced ride compliance above titanium’s legendary feel and also support tire clearance for common gravel bike options as well as fender mounts. No-nonsense rack mounting incorporates easily accessed M5 seat stay bosses and dropout threads. For the top tubes, we wanted to maximize front end stiffness under power and when cornering, but still build in compliance around the seat tube area and this meant custom tapers for these tubes.

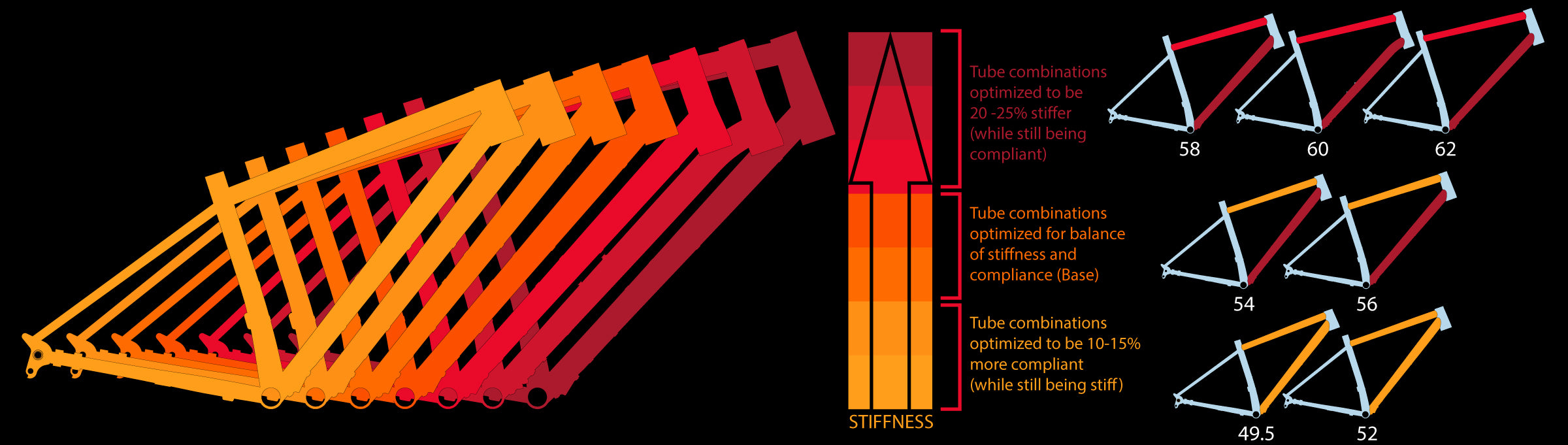

Finally, we created two separate top and two separate down tubes that we could mix and match through the Cache’s seven different frame sizes. This meant a smaller diameter, lighter weight tube set for the smallest frame sizes, a larger diameter tube set for the largest frame sizes and a mix of the two for the mid sized frames. Using a bunch of fun math, we calculated the exact stiffness profiles that we wanted for both the smaller and larger tube sets and created the diameters and tapers used in all four Cache top and down tubes. This allowed us to tailor the stiffness of the frames and increase overall frame stiffness close to 50% for the largest frame sizes, compared to the smallest frame sizes. *click image to see more details

*click image to see more details

To be honest, it’s a bit of an inexact science backed up with a lot of “feels right” testing but we think we nailed it!

Since this blog was first published when we launched the Cache Titanium, we have since released a second gravel model in steel. The Cache Steel also features custom tubing: top tubes, down tubes, seat tube, chain stay and seat stay. And for the steel version, the steel tubes are butted so that the walls are thicker where it’s welded and thinner in the middle. This reduces weight while also ensuring you have the strength needed for welding the tube ends. For more info and to shop our Cache: LINK.